What Kind Of Metal Are Bldc Motor Laminations Made Of

While electrical steel laminations are a common go to choice for custom motor components those made with nickel or cobalt alloys offer benefits that may be.

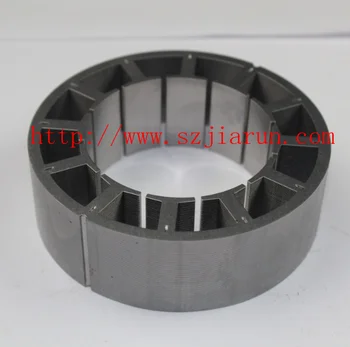

What kind of metal are bldc motor laminations made of. As a custom lamination manufacturer we can supply custom motor laminations and lam stacks in all shapes and sizes. In ac motors laminated silicon steels are used to make stators. Laminations are the steel portions of the stator and rotor consisting of thin lamination sheets stacked together either loose welded or bonded together depending on your application induction motors generators dia. Incase of dc motors the stator can permanent type or electromagnet type.

40mm to 1000mm and bldc motors dia. While copper wires are used as windings. 40 mm to 180mm. In regard to motor laminations alloys contribute to a component s output size and weight which are determined by the material s permeability saturation flux design and core losses.

Electromagnet types use soft iron or aluminium as coil. Our toolmakers are able to build and maintain a wide variety of production dies. In order to compare of the metal powder bldc motor with lamination core one three bldc motors manufactured by conventional type si core si model conventional type metal power core mp model and proposed. The applied machine is a 150w bldc motor and its stator has 12 slots and the rotor is built of 8 poles of radial magnetic ferrite magnet.