Vane Axial Fan Blade

Vane axial fans with a half blade rotor will require approximately 65 percent of the horsepower required for a full blade rotor yet will deliver the same volume cfm.

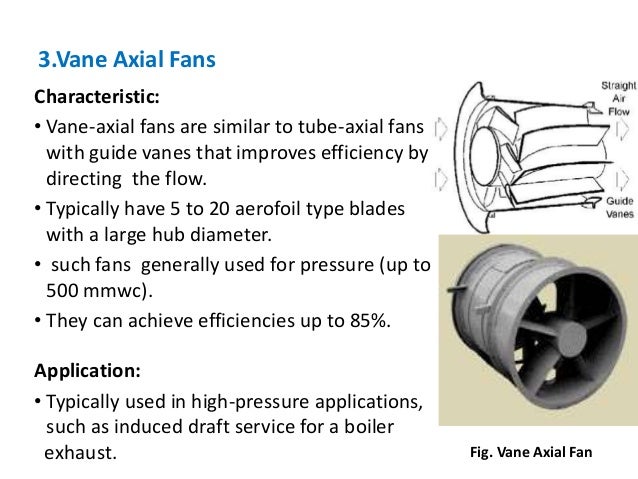

Vane axial fan blade. Half blade vane axial fans direct drive removing every other blade from the rotor has some definite advantages in low pressure selections. The inlet and outlet velocities of the air through the blades will be the same for axial fans and different for centrifugal fans v ᵢ and v ₒ. Hub and blades are constructed of aircraft quality heat treated a356 t6 cast aluminum. Jetstream axial mine fans amf series are heavy duty axial fans designed specifically for main mine ventilation these robust adjustable pitch fans have been designed to deliver up to 1 million cfm against 14 inches total pressure.

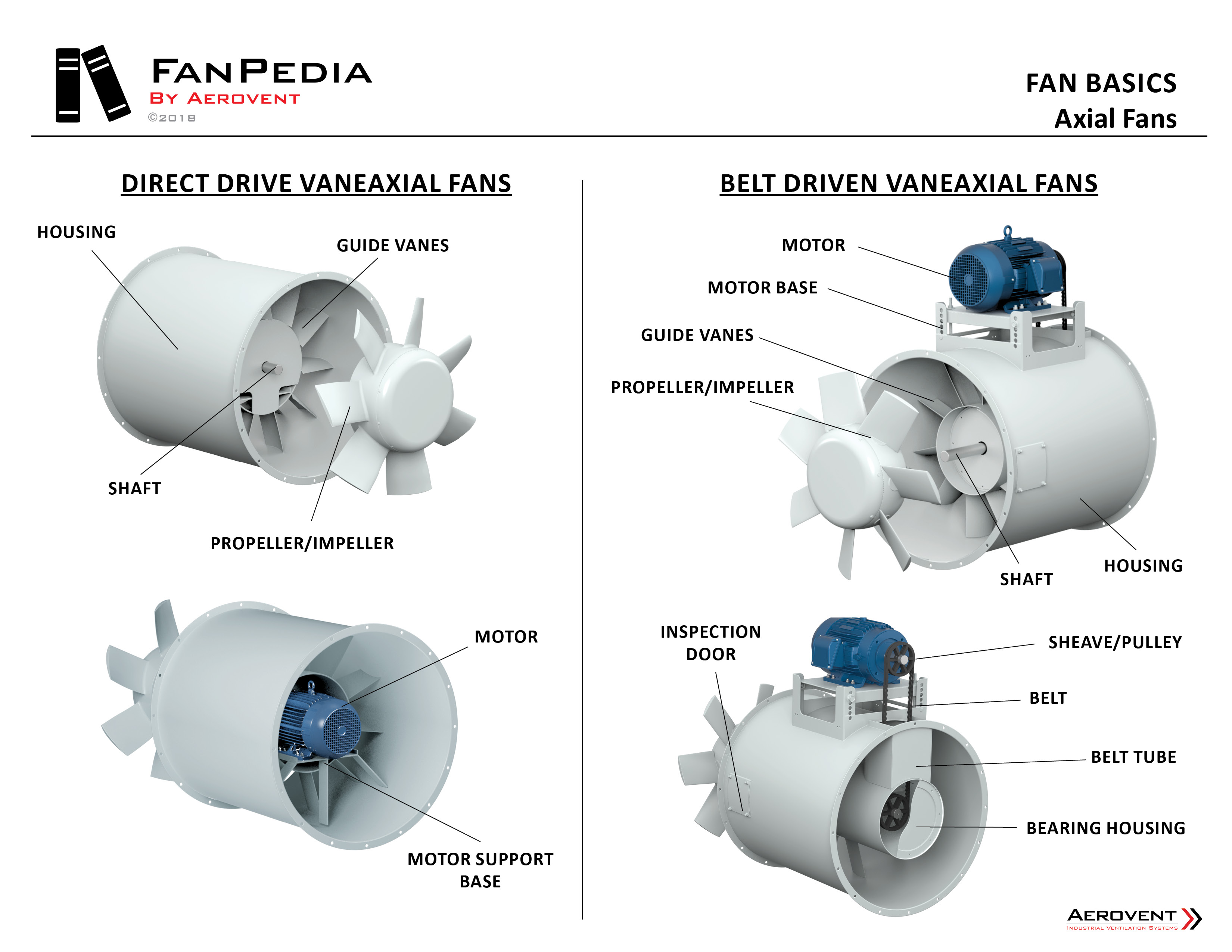

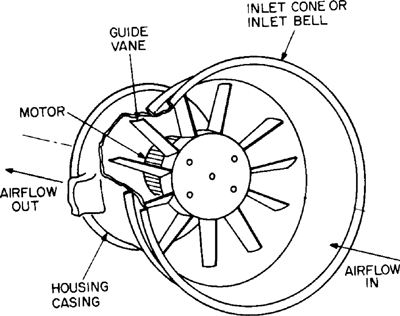

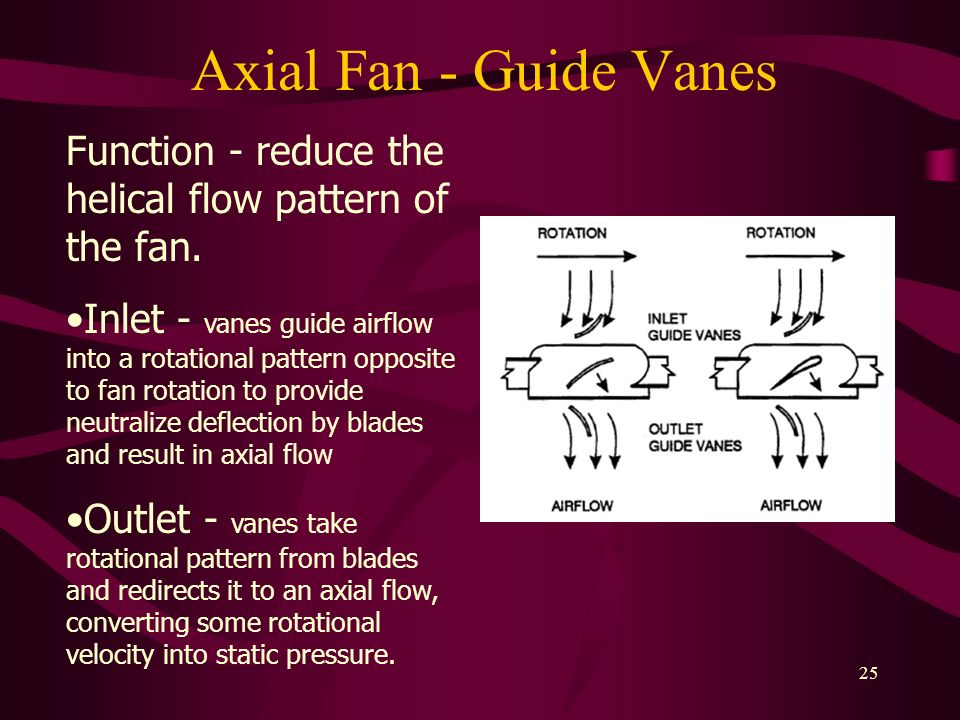

Blade bases are precision machined for an exact fit. Fan shall be a fixed pitch direct drive vane axial fan. A fan is a powered machine used to create a flow of air a fan consists of a rotating arrangement of vanes or blades which act on the air. An axial fan is a type of fan that causes gas to flow through it in an axial direction parallel to the shaft about which the blades rotate.

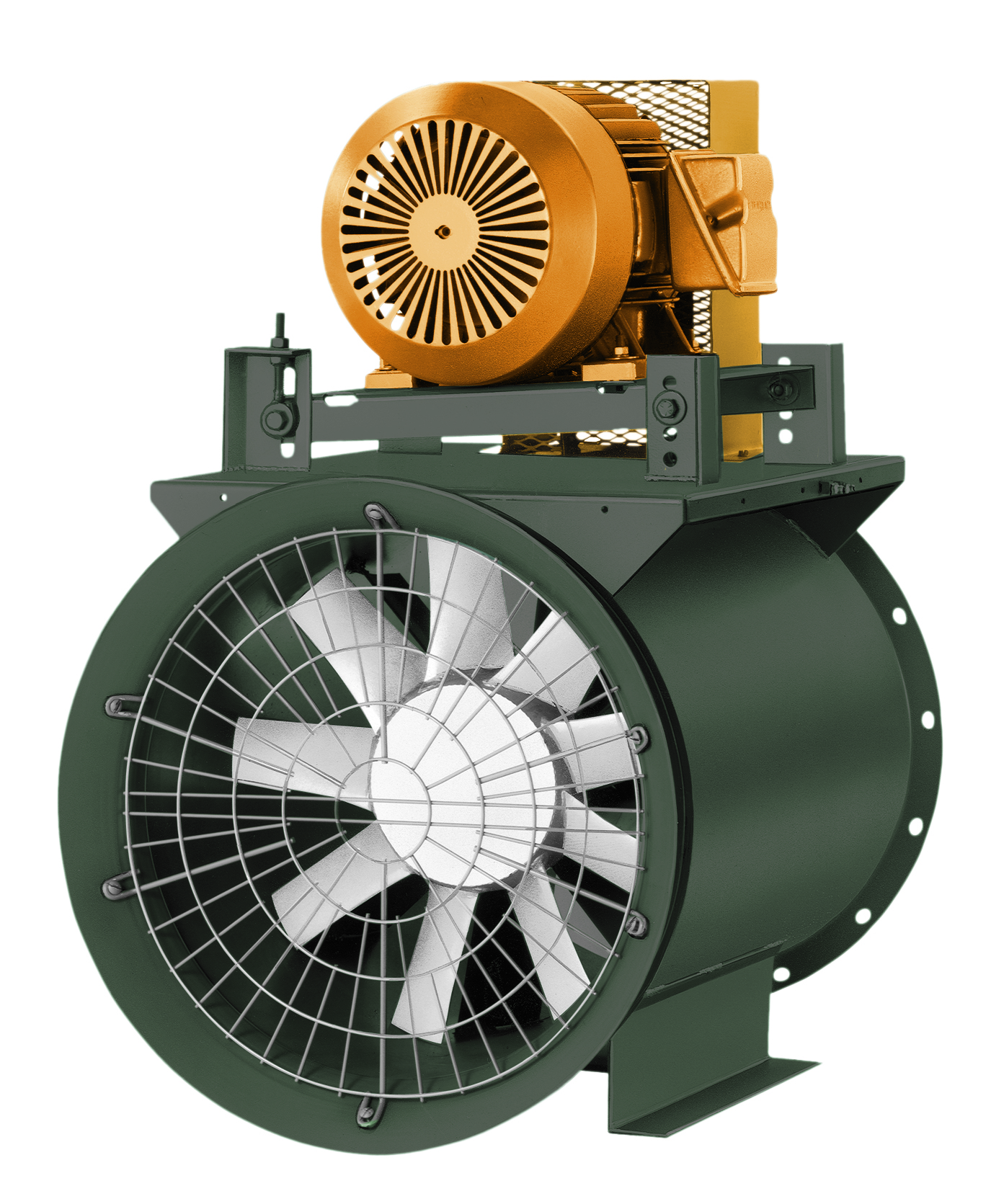

Triangle s vab vane axial belt drive fans are designed for exhausting hazardous atmospheres and corrosive fumes and are designed with pre rotative straightening vanes to boost the fans capacity to provide low cost cfm at the highest efficiency. The fan is designed to produce a pressure difference and hence force to cause a flow through the fan factors which determine the performance of the fan include the number and shape of the blades. Fan shall be manufactured at an iso 9001 certified facility. The flow is axial at entry and exit.

Limitations in the vane axial performance data brochure when making selections. Fan shall be listed by underwriters laboratories ul 705 and ul listed for canada cul 705. Rotor construction features 1. Contact us today to determine the right fan for you.

This may direct the airflow or increase safety by preventing objects from contacting the fan blades. Blade sockets are precision machined into the rotor hub. Vane axial fan direct drive. By employing selected vane to blade ratios blade twist angles blade pitch angles blade toshroud axial gaps shroud solidities vane swept angles and vane inlet and outlet angles of specified amounts or falling within specified ranges desirable fan performance is achieved.

Fig 3 shows the velocity diagram for the air flowing into the fan inlet and out of it outlet. Fan shall bear the amca certified ratings seal for sound and air performance. The rotating assembly of blades and hub is known as an impeller rotor or runner usually it is contained within some form of housing or case. Ranging in sizes from 76 1 2 to 148 this fan line delivers high efficiency and reliable service.