Top Piston Ring Material

The biggest advantage in using cast iron to manufacture pistons rings is that it will not gall or scuff the cylinder bore.

Top piston ring material. A popular material used for piston rings is cast iron often referred to as grey iron. And as long as the cast iron ring is sufficient in size it will provide adequate seal. Manufacturers use chromium plating for top rings because they are exposed to the highest working temperature and corrosion due to combustion. Maintaining the proper quantity of the oil between.

Custom piston ring materials. A flat ring groove is essential in achieving and maintaining the best seal possible. The compression ring seals the combustion chamber from any. Cast iron by nature is very brittle and therefore not as strong as gas.

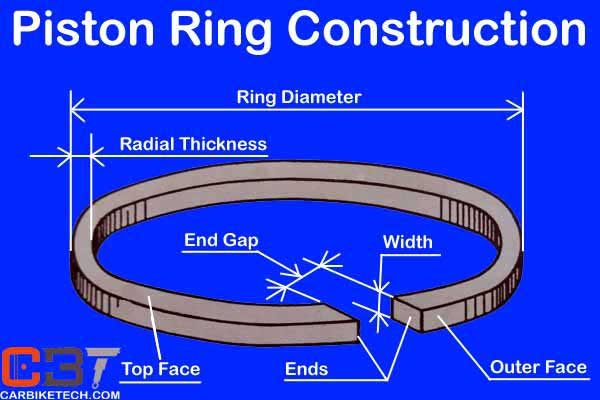

With the most comprehensive line of piston rings compression rings and oil rings in the world we have a piston ring for practically any application racing automotive heavy duty transportation agriculture industrial small engine and more. Improving heat transfer from the piston to the cylinder wall. The single most important factor to be considered in selecting the proper top compression ring face coating material is the service requirements the engine will be operated under. A piston ring is a metallic split ring that is attached to the outer diameter of a piston in an internal combustion engine or steam engine.

On top of that the company has also. The quality of the ring grooves is so critical to peak and lasting performance that mahle designed and built the machinery used to machine the ring grooves for its motorsport piston assemblies says lancaster. At hastings we manufacture a bold and broad offering of piston rings one that spans thousands of applications for virtually any engine. Generally the material used for piston rings is fine grained alloy cast iron that contains silicon and manganese.

It has good heat and wearing resistance qualities. Sealing the combustion chamber so that there is minimal loss of gases to the crank case. If for example. Piston ring size and configuration vary depending on engine design and cylinder material.

For the past decade most stock production engines have been factory equipped with steel top compression rings to handle the higher operating temperatures and loads of today s higher output engines. Polymers have good sealing characteristics for lower temperature applications. Piston rings commonly used on small engines include the compression ring wiper ring and oil ring. These can include polymers as well as the super alloys materials of high nickel or cobalt content.

The first is carbon s teel which is a much more malleable material than cast iron is able to handle higher temperatures without losing temper and is better able to withstand bouts with detonation. The main functions of piston rings in engines are. Generally speaking steel piston rings are more durable than ductile iron rings and ductile iron rings are more durable than cast iron rings. The current je piston catalog lists a multitude of ring materials which may appear at first to be a daunting challenge.