Soil Pipe Sound Insulation

This can be used for acoustic insulation on ventilation heating and air conditioning pipe work at temperatures between 0 and 700 degrees.

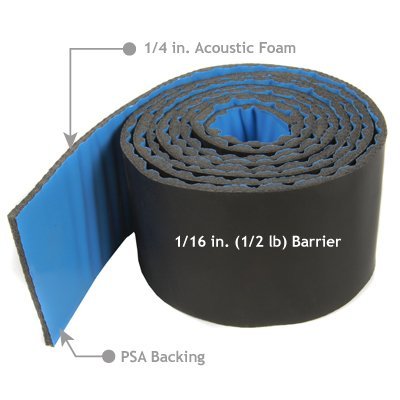

Soil pipe sound insulation. The thicker the insulation is the better. Measure the pipe s length to determine how much material you need. Peel back the edge of the blue peel and stick backing to reveal 4 to 5 inches of the backing. If one layer doesn t provide the noise reduction you were hoping for wrap it in another layer.

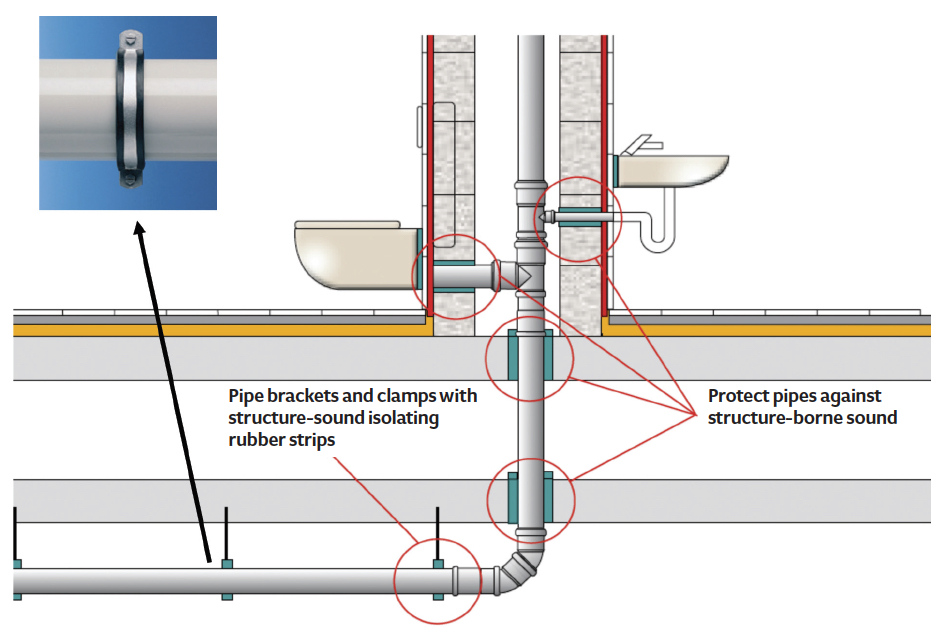

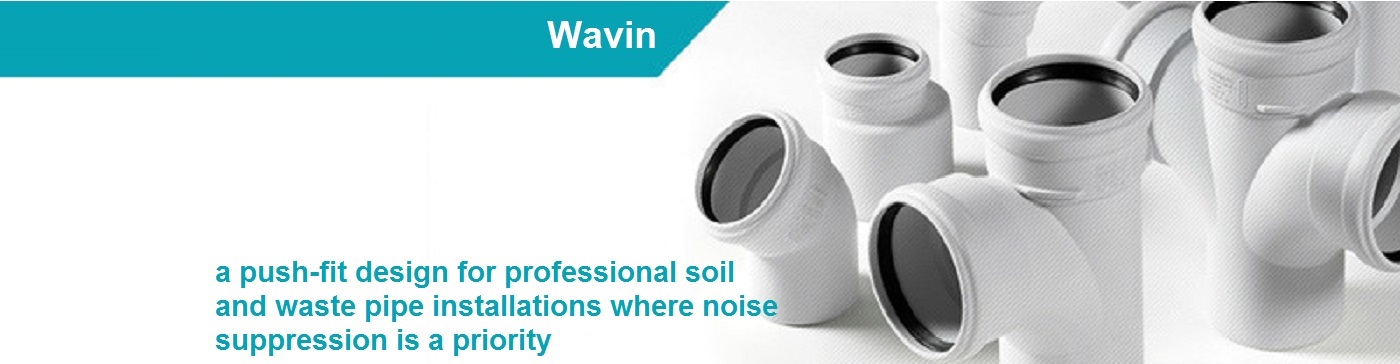

Used in conjunction with the acoustic pipe clips the dblue system is designed to reduce noise and acoustic vibrations to a level of 19db. If the material is cut lengthways in 400mm strips you will get three strips at 5 5m long. Soundproofing internal soil pipes should be viewed in two different ways. How to quiet noisy pipes.

Wrap the pipe with ft55al pipewrap overlapping at joins. Acoustic grade polyurethane foam with a peel and place adhesive backing. But if the noise persists everything points to the need for soundproofing your inner pipes. This is enough to cover a 100mm diameter.

The marley dblue acoustic soil waste system is designed for use where improved levels of soundproofing are required. Cut the pipe sound insulation to the appropriate size using a utility knife or cut the material as you wrap it around the pipe. Soundproofing internal soil pipes. The very best solution is below.

We often get asked how to deal with this. Start at one end of the pipe. How to soundproof soil and waste drainage pipes. Provides sound and thermal insulation it s self adhesive easy to cut to size with a knife and it can effectively prevent pipe bursts if adhered properly.

It has all the necessary features. The rolls are 5 5m x 1 2m. You can use a product like rocklap pipe sections which contains pre formed insulation on a roll featuring foil facing and a self adhesive backing for easy application.